Castor oil, recognized by many for its potent laxative properties, holds a far greater significance beyond this singular medicinal application, which accounts for less than 1% of its usage. In reality, castor oil is a vital raw material for the chemical industry. It serves as a base to manufacture a diverse array of products, many surpassing the performance of their petroleum-derived counterparts. The unique chemical makeup of castor oil, with 85–90% being ricinoleic acid (a hydroxy fatty acid), is what sets it apart. This high concentration of ricinoleate, at a technical grade purity, along with the presence of a hydroxyl group near a double bond, endows castor oil with distinctive physical, chemical, and even physiological characteristics, making it an exceptionally valuable commodity and industrial feedstock.

This exploration will delve into the origins of this remarkable substance, answering the fundamental question: “Where Does Castor Oil Come From?” We will journey from the plant itself to the global production landscape, uncovering the processes that transform the humble castor bean into the versatile oil that underpins numerous industries.

The Castor Plant: Ricinus Communis – Nature’s Source of Castor Oil

To understand where castor oil comes from, we must first look to its botanical source: the castor plant. Scientifically known as Ricinus communis, the castor plant is the sole species in the genus Ricinus, belonging to the Euphorbiaceae family. This fast-growing plant is native to the tropical regions of East Africa, specifically Ethiopia, and possibly India, though it has naturalized and is cultivated in tropical, subtropical, and temperate regions worldwide.

The castor plant is a striking annual or perennial shrub or small tree, capable of reaching heights of up to 12 meters (40 feet) under optimal conditions, although it is often cultivated as an annual, especially in regions with colder climates. Its large, palmate leaves, resembling those of maple trees but with serrated edges, are typically a rich green, but can also exhibit reddish or purplish hues depending on the variety. The plant is also characterized by its distinctive spiky seed pods, which are initially green and transition to brown as they mature and dry.

Mature castor beans ready for harvest

Mature castor beans ready for harvest

It is within the seeds of Ricinus communis, commonly known as castor beans, that castor oil is found. These beans are produced within the aforementioned spiky pods. Each pod typically contains three seeds, which are oval, bean-like in appearance (hence the name “castor bean,” though they are not true beans), and possess mottled, often brown and beige, patterns. The castor bean is composed of approximately 40-60% oil by weight, making it a rich source for extraction.

It’s important to note the castor plant’s dual nature. While it provides the valuable castor oil with its myriad applications, it also contains a highly toxic protein called ricin, particularly concentrated in the seeds. This toxicity necessitates careful handling and processing of castor beans to ensure safety and prevent contamination of the oil. Fortunately, ricin is not oil-soluble, meaning that properly extracted and processed castor oil is virtually free of this toxin and safe for its intended uses.

Castor Bean Cultivation and Global Production

The cultivation of castor plants is crucial to the global supply of castor oil. The plant thrives in warm climates with well-drained soil and ample sunlight. While relatively drought-tolerant, consistent moisture is beneficial, especially during seed development. Castor is commercially grown in over 20 countries across the globe, demonstrating its adaptability to various tropical and subtropical environments.

As indicated in the original article, the Food and Agriculture Organization of the United Nations (FAOSTAT) identifies India, Brazil, and China as the leading producers of castor seed. These nations consistently dominate castor bean production, contributing significantly to the global castor oil market. The following table, adapted from the original text, highlights the production figures for these key countries:

Table 4.1. Production of Castor Seed and Castor Oil, 2012–14 (in 1000 tonnes)

| Country | Seed 2014 | Seed 2013 | Seed 2012 | Castor Oil 2014 | Castor Oil 2013 | Castor Oil 2012 |

|---|---|---|---|---|---|---|

| India | 1250 | 1300 | 1280 | 563 | 585 | 576 |

| China | 71 | 105 | 145 | 31 | 46 | 63 |

| Brazil | 44 | 25 | 60 | 19 | 11 | 27 |

| Thailand | 13 | 14 | 14 | |||

| Other countries | 60 | 60 | 59 | 32 | 32 | 32 |

Data Source: Oil World, 2015

India stands out as the undisputed leader in castor production. Its favorable climate, extensive cultivation areas, and established agricultural practices contribute to its dominant position. India is not only a major producer but also a significant net exporter of castor oil, accounting for over 90% of global castor oil exports in 2014. The primary importers of castor oil include the European Union, the United States, and China, representing a substantial 84% of global imports.

Brazil and China, while also significant producers, have seen fluctuations in their production levels over the years, as reflected in the table. Other countries, categorized as “Other countries,” collectively contribute a smaller but still relevant portion to the overall global castor seed and oil production.

From Castor Bean to Castor Oil: The Extraction Process

Once castor beans are harvested, the next step in understanding “where castor oil comes from” is to examine the extraction process. Castor oil is primarily obtained from castor beans through pressing, which can be either cold-pressed or expeller-pressed, or by solvent extraction.

-

Cold Pressing: This method is considered to yield the highest quality oil, often referred to as virgin castor oil. In cold pressing, castor beans are mechanically crushed under pressure without the application of external heat. This process preserves the natural properties and nutritional components of the oil, although the yield may be lower compared to other methods.

-

Expeller Pressing: Expeller pressing is also a mechanical extraction method, but it involves more pressure and generates some heat due to friction. This method offers a higher oil yield than cold pressing and is still considered a clean and efficient extraction technique.

-

Solvent Extraction: Solvent extraction is a more industrial-scale method used to maximize oil yield. Castor beans are crushed and then treated with a solvent, typically hexane, which dissolves the oil. The oil-solvent mixture is then separated, and the solvent is evaporated, leaving behind the crude castor oil. Solvent extraction is efficient but may require further refining steps to remove any residual solvent traces and impurities.

Regardless of the extraction method, the crude castor oil obtained undergoes further processing and refining to remove impurities, color, and odor, resulting in the clear, viscous oil that is commercially available. Refining processes may include degumming, bleaching, deodorization, and filtration, ensuring the oil meets the required standards for various applications.

The Composition and Unique Properties of Castor Oil

The remarkable versatility of castor oil stems from its unique chemical composition. As highlighted earlier, ricinoleic acid constitutes the majority (85-90%) of the fatty acids in castor oil. This monounsaturated omega-9 fatty acid is unique due to the presence of a hydroxyl group (-OH) on the 12th carbon atom, which is uncommon in other vegetable oils.

Chemical structure of Ricinoleic Acid

Chemical structure of Ricinoleic Acid

This hydroxyl group, along with the double bond in the fatty acid chain, imparts several distinctive properties to castor oil:

-

High Viscosity: The hydroxyl group promotes hydrogen bonding between ricinoleic acid molecules, resulting in castor oil’s characteristic high viscosity. This viscosity is significantly higher than that of most other vegetable oils, making it valuable in lubricants, coatings, and hydraulic fluids.

-

Polarity and Solubility: The hydroxyl group also makes castor oil more polar than typical triglycerides. This polarity enhances its solubility in alcohols and other polar solvents, as well as its compatibility with various polymers and additives, expanding its applications in diverse industries.

-

Chemical Reactivity: The hydroxyl group and the double bond provide reactive sites for chemical modifications. These sites can be utilized to produce a wide array of castor oil derivatives with tailored properties for specific applications, such as polymers, surfactants, and plasticizers.

-

Biodegradability and Renewable Source: As a plant-derived oil, castor oil is a renewable resource and is generally biodegradable. This aligns with the growing global emphasis on sustainable and environmentally friendly materials, further enhancing the appeal of castor oil and its derivatives.

Diverse Applications of Castor Oil: A Testament to its Origin’s Value

The journey from “where castor oil comes from” to its vast array of applications is a testament to the ingenuity of harnessing nature’s resources. The unique properties derived from its botanical origin and chemical composition make castor oil an indispensable ingredient in numerous industries. While the original article extensively details these applications, it is worth briefly reiterating some key sectors that benefit from castor oil:

-

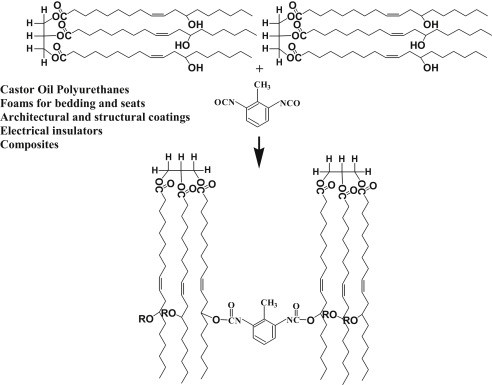

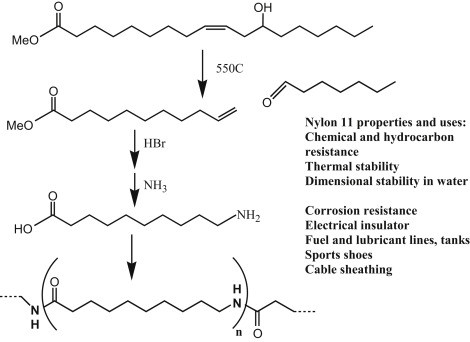

Polymers: Castor oil is a crucial renewable monomer in polymer production, particularly for polyurethanes, used in foams, coatings, elastomers, and more. Its derivatives also contribute to polyamides like Nylon 11 and PA10,10, valued for their resistance and engineering applications.

-

Plasticizers: Castor oil and its derivatives act as effective plasticizers in various polymers, enhancing flexibility, processability, and durability in products ranging from films and lacquers to PVC.

-

Soaps, Detergents, and Surfactants: Saponified castor oil contributes to soap formulations, while sulfated and ethoxylated castor oil derivatives function as surfactants and emulsifiers in detergents, cosmetics, and industrial applications.

-

Lubricants: Castor oil’s high viscosity and low cloud point make it an excellent lubricant component. Lithium greases, based on castor oil derivatives, are widely used in automotive and industrial lubrication.

-

Paints and Coatings: Dehydrated castor oil (DCO) serves as a drying oil in paints and coatings, offering waterproof and non-yellowing properties. Castor oil-based polyurethanes also find use in advanced coating formulations.

-

Fuel: Historically used as lamp fuel, castor oil continues to be explored as a biofuel component, particularly in two-stroke engines and biodiesel blends, although its higher viscosity and other properties require careful consideration for fuel applications.

-

Medicinal, Cosmetic, and Food Applications: Beyond its laxative use, castor oil and its derivatives find applications in cosmetics, particularly lipsticks, and in pharmaceutical formulations as emulsifiers. Certain derivatives are also used in food-related applications, such as mold release agents and chocolate production.

In conclusion, understanding “where castor oil comes from” reveals a fascinating story that begins with the Ricinus communis plant and its oil-rich seeds. From the tropical fields where castor plants thrive to the intricate extraction and refining processes, and finally to the diverse industries that rely on its unique properties, castor oil’s journey underscores the profound impact of botanical resources on modern life. Its versatility, rooted in its unique chemical composition and sustainable origin, ensures its continued importance as a valuable commodity and a key ingredient in a wide spectrum of products we use daily.