For generations, LEGO bricks have sparked creativity and brought joy to builders of all ages. With their mission to ‘inspire the builders of tomorrow,’ the LEGO Group has become a household name and a global powerhouse in the toy industry. But where are these iconic bricks actually made? Let’s delve into the fascinating world of LEGO production and explore the locations where these beloved toys come to life.

lego-bricks

lego-bricks

A Global Footprint of LEGO Factories

Since its humble beginnings in Denmark in 1932, the LEGO Group has expanded its reach across the globe. Today, LEGO bricks are manufactured in several key locations to meet the immense worldwide demand. The primary LEGO factories are strategically situated in:

- Denmark: The heart of LEGO, Billund, Denmark, remains a central hub for manufacturing and the company’s headquarters. This is where LEGO’s journey began, and it continues to be a vital production site.

- Hungary: LEGO has a significant factory in Nyíregyháza, Hungary. This location serves as a major production center within Europe.

- Czech Republic: Kladno in the Czech Republic is another key European manufacturing site, contributing substantially to LEGO’s global output.

- Mexico: To cater to the Americas, LEGO operates a large factory in Monterrey, Mexico. This facility ensures efficient distribution throughout North and South America.

These factories work tirelessly to produce billions of LEGO bricks each year. In 2012 alone, an astounding 45.7 billion LEGO bricks were manufactured – that’s 5.2 million bricks every hour! If you lined up all the LEGO bricks sold in just that year, they would stretch around the Earth an incredible 18 times.

lego-store

lego-store

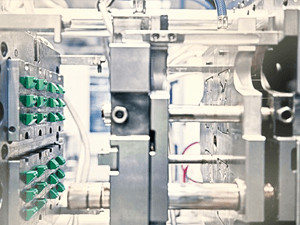

The LEGO Manufacturing Process: Precision in Every Brick

The magic behind LEGO bricks lies in the precision of plastic injection molding. The process starts with small plastic granules, which are fed into massive molding machines. Inside these machines, the granules are superheated to approximately 230 degrees Celsius (446 degrees Fahrenheit), melting them into a liquid form.

This molten plastic is then injected into meticulously crafted molds under immense pressure – hundreds of tons! This pressure ensures that every brick takes on the exact shape with incredible accuracy. The molds are so precise, with tolerances within 0.005mm, that only a tiny fraction of bricks – just 18 in every million – fail to meet LEGO’s rigorous quality standards.

Once molded, the bricks are rapidly cooled and ejected from the machines. This entire cycle, from granules to finished brick, takes a mere 10 seconds, thanks to the highly automated nature of LEGO production.

lego-plastics-injection-moulding

lego-plastics-injection-moulding

Why Location Matters for LEGO Production

The strategic placement of LEGO factories in Denmark, Hungary, Czech Republic, and Mexico is crucial for the company’s global operations. These locations offer a combination of factors that support efficient and cost-effective manufacturing and distribution:

- Proximity to Markets: Factories in Europe and Mexico allow LEGO to efficiently serve major consumer markets in Europe and the Americas, reducing shipping times and costs.

- Skilled Workforce: These regions have access to a skilled workforce capable of operating and maintaining the complex machinery involved in LEGO production.

- Infrastructure: Established infrastructure in these countries supports the logistical demands of large-scale manufacturing and global distribution.

Understanding where LEGOs are made reveals the impressive scale and global reach of this iconic toy company. From European hubs to North American centers, LEGO’s factories around the world are the engine powering the creativity and play of millions.