Oatmeal, a breakfast staple for many, is more than just a comforting and warm morning meal. Have you ever paused to consider where this wholesome grain originates before it reaches your bowl? My recent invitation from The Quaker Oats Company to join their 2019 Seed to Spoon tour at their mill in Cedar Rapids, Iowa, provided a fascinating glimpse into the journey of oats, from the fields to our tables. It was an incredibly insightful experience, and I’m excited to share the story of where your oatmeal truly comes from.

Vintage sign at Quaker Oats mill in Cedar Rapids, Iowa, highlighting the long history of oatmeal production.

Vintage sign at Quaker Oats mill in Cedar Rapids, Iowa, highlighting the long history of oatmeal production.

The Ideal Origins: Where Oats Thrive

To trace oatmeal back to its very beginning, we need to look towards the oat fields, primarily in Canada, which is where Quaker sources a significant portion of their oats. This region offers the perfect environmental conditions for oat cultivation. Oats flourish in cooler climates characterized by long, sunny days and fertile soil with good drainage. These conditions are crucial for achieving high yields and ensuring the quality of the oat grain. Interestingly, many farmers incorporate oats into their crop rotation cycles, contributing to sustainable agricultural practices. Quaker prides itself on collaborating with over 400 dedicated oat farmers through their Direct Growers Program, all committed to cultivating oats of the highest quality.

The oat harvest typically occurs in late summer or early fall. My visit to the Cedar Rapids Quaker mill in September coincided perfectly with this harvest season. The harvested oats are transported by railcar, making train whistles a familiar sound in Cedar Rapids! Quality is paramount for Quaker. Before shipping, farmers send oat samples for rigorous testing. Upon arrival at the mill, the oats undergo further examination. A representative sample from each railcar is meticulously evaluated in the lab.

Quality control lab at Quaker Oats mill where oat samples are tested for moisture, size, and composition to ensure high standards for oatmeal production.

Quality control lab at Quaker Oats mill where oat samples are tested for moisture, size, and composition to ensure high standards for oatmeal production.

These tests assess key factors like moisture content, size, and overall composition. Only shipments that meet Quaker’s stringent standards proceed to the next stage of processing. A single railcar can hold an impressive 5,000 bushels of oats, equivalent to 160,000 pounds! At peak operation, the mill can receive up to 30 railcars daily and process a staggering 3.6 million pounds of oats each day. Based on the comprehensive test results, the oats are categorized and stored in designated bins. This careful segregation allows for precise blending to meet specific nutritional claims, such as the heart health claim, which necessitates specific levels of dietary fiber and beta-glucan, ensuring the consistent high quality of Quaker’s oat products.

From Raw Grain to Oatmeal: The Milling Process

Once the oats are ready for milling, a series of essential steps transform them into the oatmeal we recognize. These stages include cleaning, dehulling, and kilning. Cleaning is critical to eliminate any non-oat materials like wheat, barley, or canola that might be present from harvesting. This cleaning process is especially vital for oats destined for gluten-free certification. Quaker maintains a zero-tolerance policy for gluten in these products, ensuring that any sample with even trace amounts of wheat or barley is rejected for their gluten-free line – a significant reassurance for those with gluten sensitivities.

Tour participants wearing safety gear including glasses, hairnets, and steel-toed shoes for a safe visit inside the Quaker Oats mill, emphasizing food safety.

Tour participants wearing safety gear including glasses, hairnets, and steel-toed shoes for a safe visit inside the Quaker Oats mill, emphasizing food safety.

Dehulling is the next step, involving the removal of the outer hull, an inedible fibrous layer. Interestingly, this hull isn’t discarded; it’s repurposed for animal feed or even used to generate electricity, showcasing a commitment to sustainability. What remains after dehulling is the inner oat groat. A helpful way to remember this distinction is: a groat is simply an oat without its “coat”!

The oat groats then undergo a unique kilning process. During my tour, I experienced the warmth firsthand – it was quite toasty! This heat treatment is crucial for deactivating naturally occurring enzymes within the groats. This deactivation process is essential for extending shelf life and developing the signature toasty flavor that is characteristic of Quaker oats. Finally, these kilned groats are prepared to be cut, flaked, and/or rolled, ultimately becoming the diverse range of Quaker oat products we find on grocery store shelves.

Oatmeal canisters on the packaging line at the Quaker Oats mill, showcasing the final stages of production before reaching grocery store shelves.

Oatmeal canisters on the packaging line at the Quaker Oats mill, showcasing the final stages of production before reaching grocery store shelves.

Rolled, Quick, or Steel Cut: Understanding Oatmeal Varieties

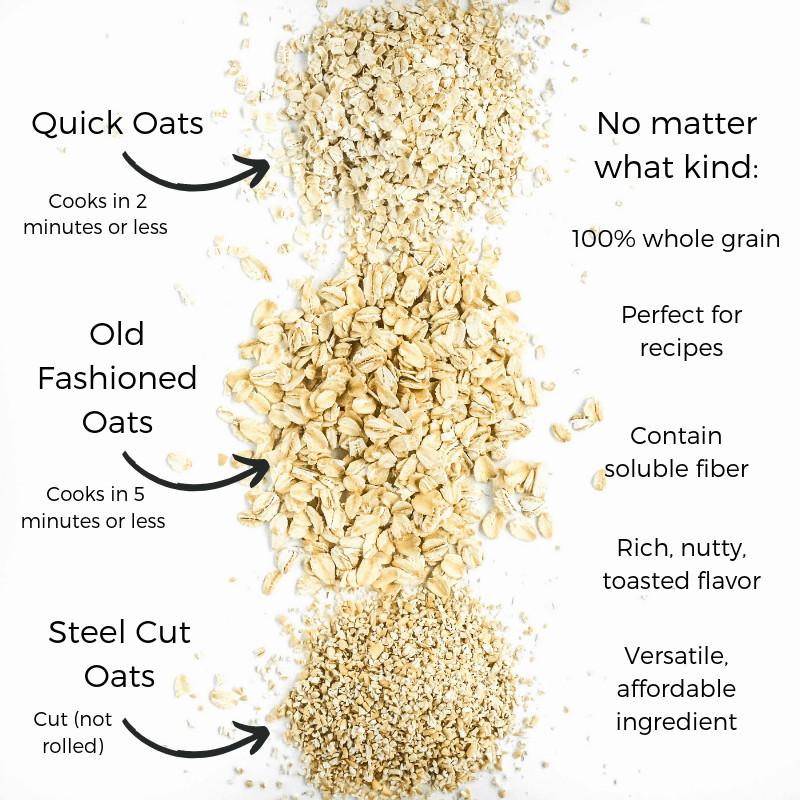

It’s fascinating to learn that all kilned groats are initially the same. The variation in oatmeal types – rolled oats, quick oats, steel-cut oats, and instant oats – arises solely from how they are processed after kilning. The primary difference lies in the size, shape, and thickness of the oat flakes. Witnessing the precision and speed of this process firsthand was remarkable. Subtle adjustments in processing result in distinct products with varying textures and cooking times, catering to different preferences and needs.

A display of various types of oats including rolled oats, quick oats, and steel cut oats in the control room of the Quaker Oats mill, illustrating processing differences.

A display of various types of oats including rolled oats, quick oats, and steel cut oats in the control room of the Quaker Oats mill, illustrating processing differences.

Without cutting and flaking, cooking oats could be a lengthy process, potentially taking hours. The flaking process involves steaming the groats and then passing them through large rollers. This significantly reduces cooking time. For quick oats and instant oats, the groats are cut into smaller pieces, further decreasing cooking time. Similarly, quick steel-cut oats are also available, achieved by cutting regular steel-cut oats into smaller fragments for faster cooking.

The specialized cutting machines for steel-cut oats were particularly impressive. Originally developed in 1875 by one of the founders of The Quaker Oat Company, the steel knives and cutting technology have undergone significant advancements since then. As someone fascinated by the history of food, gaining insight into the story behind oats and their processing was a highlight of my experience.

The Nutritional Powerhouse: Oat Nutrition

With so many oat varieties available, you might wonder about their nutritional differences. The good news is that nutritionally, ounce per ounce, all types of oats – Old Fashioned, Quick, Instant, and Steel Cut – offer similar amounts of fiber, vitamins, and minerals. All varieties are 100% whole grain, with the only distinctions being texture, shape, and cooking time.

Infographic comparing steel cut oats and rolled oats, highlighting the texture and processing differences between various oatmeal types for consumers.

Infographic comparing steel cut oats and rolled oats, highlighting the texture and processing differences between various oatmeal types for consumers.

A common question is whether one type of oat is more nutritious than another. You can confidently choose whichever type you enjoy most! Some prefer the creamy texture of instant or old-fashioned oats, while others favor the chewier texture of steel-cut oats. Time also plays a role in oat selection. Quick and instant oats are faster to prepare, making them convenient for busy mornings.

Beyond the inherent nutritional value of oats, their versatility truly shines. Oats serve as a fantastic base for countless flavorful and nutritious meals and snacks. They are a blank canvas for culinary creativity, lending themselves to sweet and savory dishes, hot and cold preparations, and even smoothies. The possibilities are endless!

Fast-moving conveyor belts and scales in the Quaker Oats mill, demonstrating the efficiency and precision of oatmeal packaging and processing.

Fast-moving conveyor belts and scales in the Quaker Oats mill, demonstrating the efficiency and precision of oatmeal packaging and processing.

Touring the oat mill in Cedar Rapids with the Quaker Oats team and fellow dietitians and food bloggers provided a profound appreciation for the quality, nutritional value, and dedication that goes into every serving of oatmeal. I left with a renewed understanding and passion for oats, eager to translate this knowledge into creating even more delicious recipes featuring this incredible grain. If you’re feeling inspired, explore the current oat recipes available and perhaps discover your new favorite way to enjoy oatmeal!