The name “Three Mile Island” is globally recognized, often associated with the 1979 nuclear accident that significantly impacted the nuclear power industry. But for many, the immediate question might be: Where Is Three Mile Island located? Three Mile Island is situated in the Susquehanna River, in Dauphin County, Pennsylvania, just a few miles southeast of the city of Harrisburg, the state capital. More precisely, it’s about 10 miles southeast of Harrisburg, making it geographically close to a significant population center in the northeastern United States.

Geographically, Three Mile Island is not actually an island in the traditional sense of being surrounded by ocean. It’s a landmass within the Susquehanna River, a major river system flowing through Pennsylvania and Maryland. The power plant complex occupies a portion of this island, which was chosen for its access to the river’s water for cooling purposes, a critical requirement for nuclear power generation. The location near Harrisburg placed it within reach of energy grids serving the populous Mid-Atlantic region.

Aerial view of Three Mile Island Nuclear Generating Station in Pennsylvania, USA, highlighting its island location in the Susquehanna River and proximity to Harrisburg, emphasizing the geographical context of the nuclear power plant.

The History of Three Mile Island Power Station

The Three Mile Island Nuclear Generating Station was initially built with two pressurized water reactors (PWRs). Unit 1 (TMI-1) began commercial operation in 1974. This reactor, with a gross capacity of 880 MWe (net 819 MWe), became known for its consistent high performance and reliability within the US nuclear energy sector until its eventual shutdown in 2019. Unit 2 (TMI-2), a slightly larger PWR with a gross capacity of 959 MWe (net 880 MWe), was newer, having just come online shortly before the infamous accident.

At the time of the accident in 1979, Three Mile Island was operated by Metropolitan Edison Company. The plant was designed to contribute significantly to the energy needs of Pennsylvania and the broader region, harnessing nuclear fission to produce electricity. The choice of location on Three Mile Island was strategic for its access to cooling water from the Susquehanna River, a standard practice for thermal power plants, including nuclear facilities.

The 1979 Accident at Three Mile Island Unit 2

The event that catapulted Three Mile Island into global consciousness occurred in the early morning hours of March 28, 1979. At 4 a.m., while operating at 97% power, TMI-2 experienced a malfunction in its secondary cooling circuit. This seemingly minor issue triggered a chain of events that culminated in a partial meltdown of the reactor core.

The initial problem was a cooling malfunction in the secondary circuit, which caused the temperature in the primary coolant to rise. This rise in temperature automatically triggered a reactor shutdown – a safety mechanism designed to halt the nuclear fission process. The reactor shut down in approximately one second, as intended. However, what followed was a cascade of errors and equipment failures compounded by misinterpretations and inadequate training.

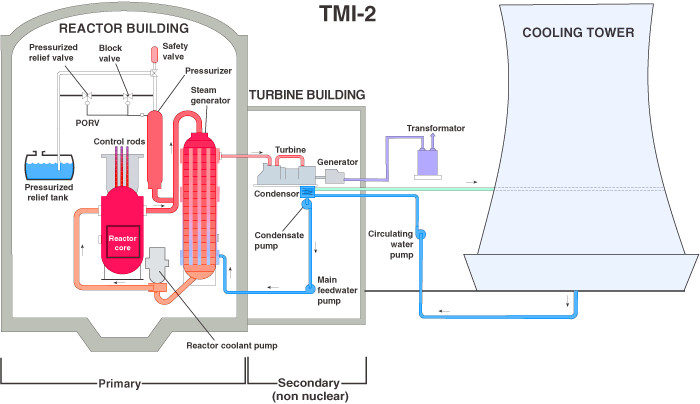

A pilot-operated relief valve (PORV) on the reactor cooling system opened as designed during the shutdown. About ten seconds later, it should have closed to maintain pressure in the primary system. However, the PORV failed to close, remaining stuck in the open position. Crucially, the control room instrumentation provided misleading information. Operators received a signal indicating that a “close” command had been sent to the valve, leading them to believe it was shut. Unfortunately, there was no direct indication of the valve’s actual position – open or closed.

With the relief valve stuck open, vital reactor coolant water began to drain out of the primary system and into the reactor coolant drain tank. This loss of coolant initiated an automatic response: high-pressure injection pumps activated, pushing replacement water into the reactor system to compensate for the loss. As steam and water continued to escape through the open relief valve, the incoming cooling water caused the water level in the pressurizer to rise.

The pressurizer is a critical component in a PWR, a tank connected to the primary cooling system designed to maintain proper pressure. It’s where the relief valve was located. In PWRs like TMI-2, the water circulating around the reactor core in the primary cooling system is kept under immense pressure to prevent it from boiling.

Operators, relying on their training, focused on the rising water level in the pressurizer. Their training emphasized the pressurizer water level as the primary and most reliable indicator of the amount of coolant in the system. Seeing the level increasing, they incorrectly concluded that the reactor system was becoming overfilled with water. Their procedures directed them to prevent the pressurizer from becoming completely full, fearing a loss of pressure control and potential rupture of the cooling system. Consequently, they manually reduced the flow of replacement cooling water being injected by the high-pressure pumps, exacerbating the loss of coolant from the reactor core.

As coolant water continued to escape through the stuck-open relief valve and less replacement water was injected due to operator actions, steam began to form within the reactor’s primary cooling system. Pumping a mixture of steam and water caused severe vibrations in the reactor cooling pumps. Concerned about potential damage to these pumps, which were essential for forced cooling of the reactor core, operators shut them down. This action eliminated forced cooling of the reactor core, though operators still incorrectly believed the system was nearly full of water due to the misleading pressurizer level indication.

With forced cooling stopped and coolant continuing to boil off, the reactor’s fuel core became uncovered and began to overheat dramatically. The fuel rods, made of zirconium alloy cladding containing uranium fuel pellets, sustained significant damage. The extreme heat caused a chemical reaction between the zircaloy cladding and the steam, producing hydrogen gas and further escalating the situation. Radioactive materials, including fission products, were released from the damaged fuel rods into the reactor cooling water.

At 6:22 a.m., more than two hours after the initial malfunction, operators finally closed a block valve upstream of the relief valve. This action effectively stopped the ongoing loss of coolant water through the stuck-open relief valve. However, by this point, superheated steam and non-condensable gases, including hydrogen, had accumulated in the reactor vessel, impeding the flow of cooling water and hindering efforts to re-establish effective core cooling.

Throughout the morning and into the afternoon, operators struggled to restore adequate cooling. They attempted to inject more water into the reactor system to condense the steam bubbles that they believed were blocking coolant flow. Later in the afternoon, they tried to reduce pressure in the reactor system to enable the use of a low-pressure emergency cooling system and to inject emergency water supplies.

Restoring Cooling and Radioactive Releases

By late afternoon, operators began to increase high-pressure injection of water into the reactor cooling system, aiming to raise pressure and collapse the steam bubbles. Finally, at 7:50 p.m. on March 28, nearly 16 hours after the accident began, they successfully restarted one reactor coolant pump, restoring forced cooling to the reactor core. They had managed to condense enough steam to allow the pump to operate without damaging vibrations.

Although core cooling was eventually restored, the accident had already resulted in significant core damage and a release of radioactive materials within the plant. Radioactive gases from the reactor cooling system accumulated in the makeup tank in the auxiliary building. On March 29 and 30, operators initiated a process to transfer these gases to waste gas decay tanks using a system of pipes and compressors. Unfortunately, leaks in the compressor system led to the release of some radioactive gases into the environment.

These releases passed through high-efficiency particulate air (HEPA) filters and charcoal filters designed to remove most radioactive particles and iodine. However, noble gases, such as xenon and krypton, are not effectively removed by these filters. It is estimated that approximately 370 PBq (Petabecquerels) of noble gases were released. While detectable, these noble gases are biologically inert and have short half-lives, meaning they decay relatively quickly and do not concentrate in the body. Consequently, health authorities concluded that these releases did not pose a significant health hazard to the surrounding population, with radiation doses remaining close to background levels for local residents.

The Hydrogen Bubble and Public Anxiety

A significant concern arose from the formation of a hydrogen bubble within the reactor vessel. The high-temperature reaction between the superheated steam and the zirconium alloy fuel cladding, which occurred when the core was uncovered on the morning of March 28, produced a substantial amount of hydrogen gas. Later that afternoon, a sudden pressure spike within the reactor building, registered by control room instruments, indicated a hydrogen burn had occurred within the containment. Hydrogen gas also accumulated at the top of the reactor vessel, forming a “bubble”.

From March 30 to April 1, operators worked to remove this hydrogen bubble by periodically venting gas from the reactor cooling system pressurizer. For a period, officials at the Nuclear Regulatory Commission (NRC) expressed concern that this hydrogen bubble could potentially explode. However, it was later determined that a hydrogen explosion within the reactor vessel was not possible due to the lack of sufficient oxygen in the closed system.

The hydrogen bubble incident, combined with communication challenges and misinformation, significantly heightened public anxiety and fear in the days following the accident. The drama and uncertainty of this period, particularly on Friday, March 30, and Saturday, March 31, are well-documented in “Crisis Contained, The Department of Energy at Three Mile Island“, an official history by Philip L Cantelon and Robert C. Williams (1982).

Misunderstandings and communication breakdowns between state and federal agencies fueled public concern. Confused telephone conversations led to misinterpretations of radiation readings and the perceived threat of further explosions. An inaccurate report of a 1,200 millirems (12 mSv) radiation reading being “off-site” (it was actually measured directly above the plant’s auxiliary building stack) amplified fears. Rumors of an impending hydrogen explosion and a potential meltdown further escalated the situation.

Media reports, often based on garbled communications, contributed to a debate over evacuation. While no official evacuation order was issued, a significant voluntary exodus occurred over the weekend. This “weekend exodus” was driven not by the actual conditions at Three Mile Island, but by public perception of potential dangers fueled by confused communications and media reports, creating a “politics of fear,” as described in “Crisis Contained“.

Despite the public alarm, extensive environmental sampling conducted by the Department of Energy and the Pennsylvania Department of Environmental Resources around Three Mile Island during the accident period revealed no unusually high radiation readings, with the exception of noble gases. Iodine levels, a key indicator of more serious radioactive releases, were virtually undetectable. Radiation levels remained far below established health limits. However, the political and public perception storm raged on, driven by misinformation and anxiety.

Cold Shutdown, Investigation, and Long-Term Health Studies

After a tense month of managing the aftermath of the accident, operators achieved a stable “cold shutdown” state on April 27. Natural convection circulation of coolant was established, meaning the reactor core was being cooled by the natural movement of water rather than forced pumping. “Cold shutdown” signifies that the reactor was in a safe and stable condition, with the water temperature below 100°C at atmospheric pressure.

The long and complex process of investigating the extent of the damage and cleaning up the TMI-2 reactor began. In July 1984, the reactor pressure vessel head was removed, allowing access to the damaged core. Subsequent investigations revealed that a significant portion of the core – at least 45%, or approximately 62 tonnes – had melted. Around 19 tonnes of this molten material (corium) had relocated to the lower plenum of the reactor vessel, primarily in the lower head. However, remarkably, the reactor vessel itself had maintained its integrity, preventing a breach of containment. Most of the melted core material remained within the original core region.

Further analysis, including samples taken by the multinational OECD Vessel Investigation Project (VIP) in 1988, confirmed that the damage to the reactor vessel was less severe than initially feared.

Extensive public health concerns arose in the aftermath of the accident, focusing on the potential for radiation-induced health effects, particularly cancer, in the communities surrounding Three Mile Island. To address these concerns, the Pennsylvania Department of Health established a registry tracking over 30,000 individuals who resided within a five-mile radius of Three Mile Island at the time of the accident. This registry was maintained for 18 years, until mid-1997, without revealing any statistically significant unusual health trends in the monitored population.

Numerous major independent health studies were conducted to assess the long-term health impacts of the Three Mile Island accident. These studies consistently found no evidence of an elevated incidence of cancer or other adverse health outcomes attributable to the accident in the years following 1979. The only detectable health effect was psychological stress experienced by residents during and immediately after the crisis.

These studies corroborated the findings that radiation releases during the accident were minimal, far below levels known to cause radiation-related health effects. The average radiation dose to individuals living within 10 miles of the plant was estimated to be just 0.08 millisieverts (mSv), with no single individual receiving more than 1 mSv. To put this in perspective, 0.08 mSv is roughly equivalent to the radiation dose from a chest X-ray, and 1 mSv is about one-third of the average annual background radiation exposure for US citizens. It is generally accepted that radiation doses exceeding 100 mSv within a short timeframe are necessary to slightly increase the lifetime risk of cancer.

In 1996, a class-action lawsuit alleging health effects from the accident was dismissed by Harrisburg US District Court Judge Sylvia Rambo. The judge cited evidence indicating that the maximum offsite radiation dose was likely around 1 mSv, projecting fewer than one potential fatal cancer attributable to the accident. She also highlighted the plaintiffs’ lack of evidence to support claims of unreported hydrogen “blowouts” and radiation “spikes.” The dismissal was upheld upon appeal.

Decades of scientific scrutiny and numerous independent studies have consistently failed to establish any link between the Three Mile Island accident and adverse long-term health consequences, beyond transient psychological stress.

The TMI-2 Clean-up and Unit 1’s Legacy

The clean-up operation at the damaged TMI-2 reactor was an unprecedented and technically challenging undertaking. It spanned nearly 12 years and cost approximately $973 million. The process involved decontaminating plant surfaces, processing and managing contaminated water, and removing approximately 100 tonnes of damaged uranium fuel from the reactor vessel – all while ensuring the safety of clean-up workers and the public.

A comprehensive clean-up plan was developed and executed by a team of over 1,000 skilled workers. It commenced in August 1979, with the initial shipments of low-level radioactive waste generated by the accident to a disposal site in Richland, Washington. Defueling the reactor core was a central and complex aspect of the clean-up. Damaged fuel was handled underwater throughout the process. Starting in October 1985, workers using long-handled tools from a platform above the reactor began carefully lifting fuel debris into specially designed canisters. A total of 342 fuel canisters were eventually shipped to the Idaho National Laboratory for long-term storage, a program completed in April 1990. The damaged fuel is now in dry storage within concrete containers.

By 1991, final measurements confirmed that approximately 99% of the fuel had been removed from the reactor vessel, with about 1% remaining in inaccessible areas. The last remaining contaminated water was pumped out of the TMI-2 reactor in 1991. The formal clean-up program concluded in December 1993, when Unit 2 received a license from the NRC to enter post-defueling monitored storage (PDMS).

Early in the clean-up process, TMI-2 was physically separated from Unit 1, ensuring the operational independence of the still-intact Unit 1 reactor. Today, TMI-2 remains in long-term monitored storage. No future use of the nuclear components of TMI-2 is anticipated. Systems for ventilation and rainwater are continuously monitored, and equipment necessary for maintaining safe long-term storage is regularly maintained.

Despite the TMI-2 accident, Unit 1 at Three Mile Island had a distinct and positive operational history. Following a post-accident shutdown for modifications and safety upgrades, TMI-1 restarted in 1985 and operated with exceptional safety and reliability until its shutdown in September 2019. The lessons learned from the TMI-2 accident were rigorously applied to enhance the design, operations, and training at TMI-1, contributing to its strong performance record.

TMI-1 achieved numerous operational milestones, including a record-breaking 616 days and 23 hours of continuous operation in 1997, then the longest run for any light water reactor worldwide. It consistently earned high safety ratings from the NRC and demonstrated excellent capacity factors, often exceeding industry averages. However, despite its strong operational record, economic factors and changing energy market conditions led to the decision to shut down TMI-1 in 2019.

Lasting Impacts: Safety Improvements and Public Perception

The Three Mile Island accident, while not resulting in widespread physical harm, had profound and lasting impacts on the nuclear power industry and public perception of nuclear energy. The accident served as a critical learning experience, prompting significant improvements in nuclear plant safety, operator training, and regulatory oversight worldwide.

One of the most significant outcomes was a fundamental shift in operator training. The “symptom-based” approach to emergency response was developed and implemented, emphasizing the immediate priority of maintaining core cooling, regardless of the initiating event. Operators are now trained to follow diagnostic procedures based on observable plant symptoms rather than relying solely on pre-defined scenarios.

The accident also led to the creation of the Institute of Nuclear Power Operations (INPO) in 1979 and its National Academy for Nuclear Training in 1985. These industry-led organizations play a crucial role in promoting excellence in nuclear plant operations and accrediting training programs across the US nuclear industry. INPO and similar organizations globally have been instrumental in standardizing best practices and fostering a culture of safety within the nuclear sector.

Enhanced communication and teamwork became integral components of operator training. Simulator training, using sophisticated full-scale control room simulators like the $18 million simulator at TMI, became standard practice, allowing operators to practice and be evaluated on a wide range of accident scenarios in a realistic environment.

The collective effect of these training improvements, operational enhancements, and strengthened regulatory oversight has been a demonstrably safer and more reliable nuclear power industry. Key indicators, such as the number of significant plant events reported to the NRC and plant capacity factors, show substantial improvements since the 1980s. Nuclear plants today operate with a much higher degree of safety and reliability compared to the era preceding the Three Mile Island accident.

However, the accident also had a lasting negative impact on public confidence in nuclear energy, particularly in the United States. The confusion, fear, and misinformation surrounding the event significantly eroded public trust. The Three Mile Island accident is widely considered a major factor contributing to the slowdown in nuclear power plant construction in the US and other countries during the 1980s and 1990s.

In summary, while the Three Mile Island accident was a serious event involving significant reactor core damage, it was contained, and radiation releases were minimal with no demonstrable long-term health consequences for the public. The accident’s most enduring legacy is the extensive safety improvements it spurred within the nuclear industry, making nuclear power plants safer and more reliable today. And to answer the initial question, Three Mile Island, the location of this pivotal event in nuclear history, remains situated in the Susquehanna River near Harrisburg, Pennsylvania, a place forever linked to the lessons learned and the progress made in nuclear safety.

Sources

GPU Nuclear Corp., 10 briefing papers, 1999

Nuclear Energy Institute, Nuclear Energy Overview 08/05/2000

Related Information

Cooperation in Nuclear Power

Safety of Nuclear Power Reactors